How Jacobsen Salt Co.'s Salt Making Process Results in Great Tasting Salt

Posted by:

Jacobsen Salt Co.

Posted on:

Feb 04, 2019

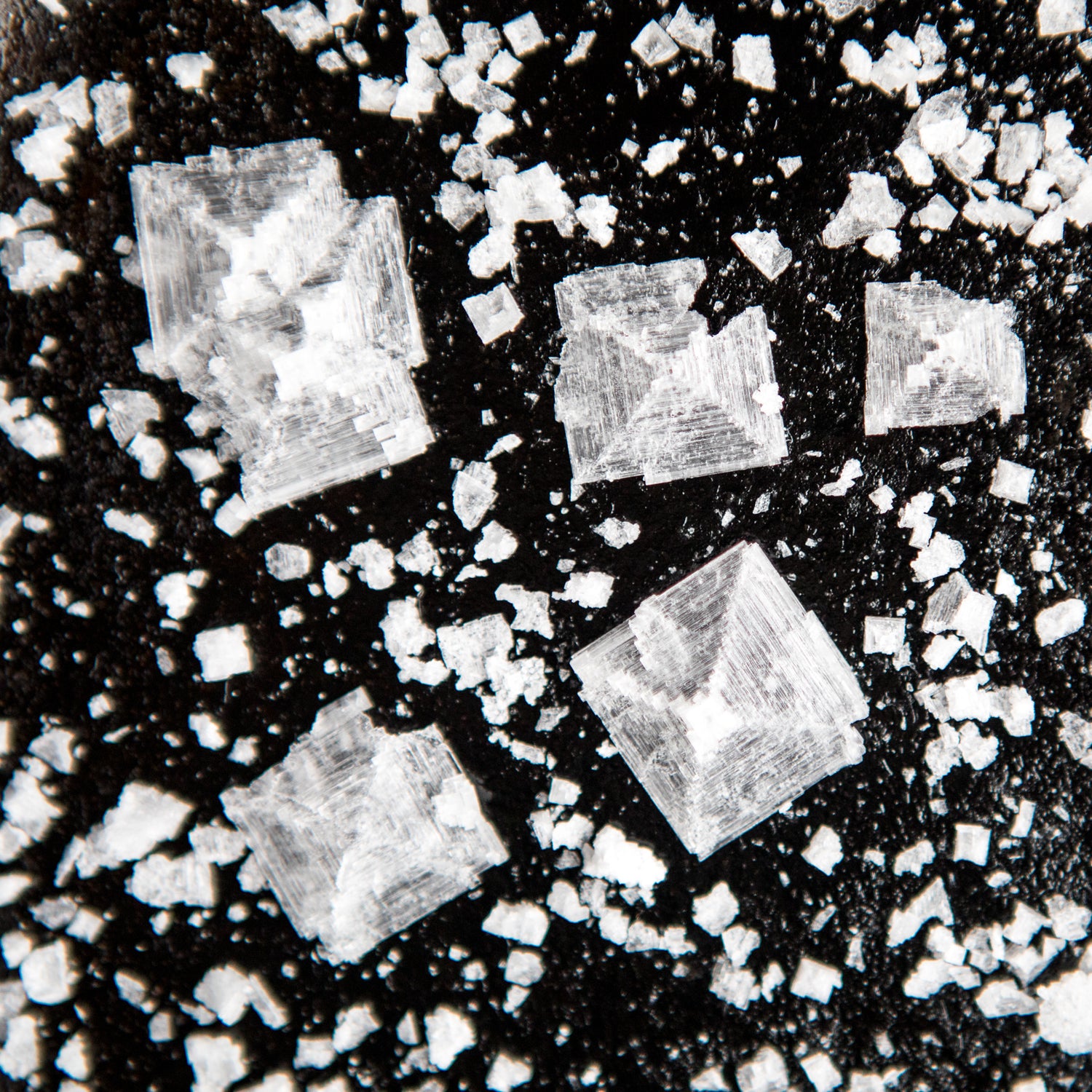

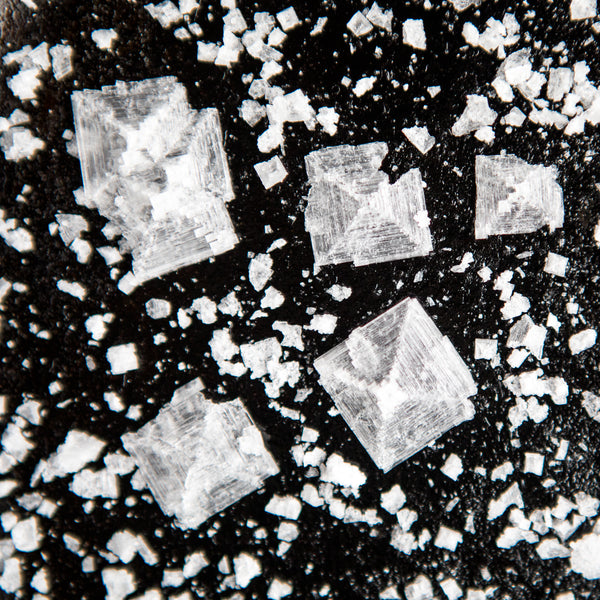

We believe that taste, texture, and color are the hallmarks of a great salt. We take great pride in our salt making process, producing salt that is bright and briny with a delicate crunch and no bitter aftertaste. In order to make our exceptional salt, much of our salt making is focused on removing anything that would interfere with crystal formation and create off-flavors and colors.

It all starts with our location– the pristine waters of Netarts Bay. After testing water from 27 different locations, we settled on this site: a relatively shallow estuary that is home to millions of oysters and other bivalves, which help filter the seawater. This helps create water that is high in salinity and low in turbidity, which has also been essentially prefiltered before it reaches our saltworks.

Next, all of the seawater we pump in from the ocean is filtered at least three times before salt crystallization begins. First, seawater is filtered for any larger debris that may be naturally found in the ocean. Then, the water is passed through a series of filters that removes anything larger in size than 0.5 microns including bacteria and other microscopic impurities.

After harvesting, we rinse our salt to remove naturally occurring minerals, specifically calcium and magnesium, that can make sea salt taste bitter. Additionally, rinsing our salt promotes even drying and less clumping, leaving a beautiful, individual salt crystal of the highest purity. This process leaves us with the signature clean and briny taste that people have come to know and love.

For more on our process visit us at https://jacobsensalt.com/pages/about-jacobsen-salt-co.